RENEWABLE ENERGY TEST SOLUTIONS

OVERVIEW

Renewable energy technologies have become increasingly popular in recent years as a way to reduce reliance on fossil fuels and mitigate the effects of climate change. However, ensuring the reliability and performance of these technologies is crucial to their widespread adoption and Rexgear acknowledges and addresses the crucial global need to target Carbon Neutrality and Net-Zero Carbon Dioxide Emissions, our part is to help manufacturers test products such as Solar Cells, Solar Panels, Solar Inverters and Wind Turbines. This application note will provide an in-depth overview of renewable energy testing, its importance, and the different methods used for testing.

INTRODUCTION TO RENEWABLE ENERGY TESTING

Renewable energy testing involves the evaluation of renewable energy technologies to ensure that they meet specific performance and reliability criteria. Testing is typically done during the development phase, manufacturing and quality assurance but in the majority of the cases is conducted throughout the life of the technology to assess its performance over time.

IMPORTANCE OF RENEWABLE ENERGY TESTING

Renewable energy technologies are complex systems that require rigorous testing to ensure that they are reliable and perform as intended. Testing helps to identify any weaknesses or potential failures in the system, which can then be addressed before the technology is deployed. This reduces the risk of downtime, improves efficiency and ultimately saves money.

In addition, testing is also essential for regulatory compliance. There are many regulations in the United States and through the American Continent that require renewable energy systems to meet specific performance standards before they can be deployed. Testing ensures that these standards are met, and that the technology is safe for use. REXGEAR has all the tools you need to be able to test to these standards.

METHODS OF RENEWABLE ENERGY TESTING

There are several methods used for testing, depending on the type of technology being evaluated. Some of the most common methods include:

• PERFORMANCE TESTING

Performance testing involves measuring the output of a renewable energy system under various conditions. This includes measuring the power output of a Solar Cell or Solar Panel, exercising the input conditions and output response of a PV Inverter or Wind Turbine. Performance testing is typically done in a laboratory setting, where the conditions can be controlled and measured accurately.

• RELIABILITY TESTING

Reliability testing involves subjecting a renewable energy system to various stress tests to identify any potential weaknesses or failures. This includes testing the system under extreme temperature or weather conditions, such as thermal shock, heavy rain, salt water or a combination of all. Reliability testing can be also done in a laboratory setting, where real-world conditions are simulated.

• DURABILITY TESTING

Durability testing involves testing the materials and components used in a renewable energy system to ensure that they can withstand the rigors of long-term use. As an example, this includes testing the durability of solar panels or the resilience of wind turbine blades. Durability testing is typically done in a laboratory setting, where the conditions can be controlled and measured accurately. REXGEAR’s Vibration, Shock and Drop test systems are ideal for some of these durability testing requirements.

• ENVIRONMENTAL TESTING

Environmental testing involves subjecting a renewable energy system to various environmental conditions to ensure that it can withstand exposure to the elements. This includes testing the system's resistance to extreme temperatures, humidity and salt spray. Environmental testing is typically done in a laboratory setting, where the conditions can be controlled and measured accurately.

• CONCLUSION

Renewable energy testing is essential to ensure that renewable energy technologies are reliable, efficient and safe for use. There are several methods used for testing, including performance testing, reliability testing, durability testing, and environmental testing. Each method has its own unique benefits and challenges, and the choice of method depends on the type of technology being evaluated. Through rigorous testing, renewable energy technologies can be developed and deployed with confidence, leading to a more sustainable and resilient future.

SOLAR INVERTER TESTING

INTRODUCTION TO SOLAR INVERTER TESTING

A Solar Inverter is an essential component of a solar energy system, converting DC power from solar panels to AC power for use in homes or businesses. Ensuring the reliability and performance of PV inverters is critical to the successful deployment of solar energy systems. That's why PV inverter test systems are crucial. This application note provides a comprehensive overview of PV inverter test systems, their importance, and the different methods used for testing.

TEST SYSTEM COMPONENTS

The components of a PV inverter test system include:

• GRID SIMULATOR / AC LOAD

The Grid Simulator / AC Load presents the Grid or a simulated AC Load to the inverter, allowing for the measurement of its performance under various voltage and frequency conditions. In addition to the Grid, in order to test for Anti-Islanding, the load bank can be either resistive or inductive, depending on the type of inverter being tested.

• INPUT / OUTPUT MEASUREMENT AND SIMULATION

Input / Output Voltage and Current measurements and simulation are used to determine the Solar Inverter’s performance. These measurements provide critical information about the inverter's performance, limitations and efficiency.

• DATA ACQUISITION SOFTWARE

Data acquisition software is used to record and analyze the data collected during the testing process. The software allows for the creation of performance graphs and charts, making it easier to identify any potential issues with the inverter.

• FUNCTIONAL TESTING BASICS

Functional testing of PV inverters is critical to ensure that they operate correctly and safely. A well-defined test procedure is essential to verify the inverter's compliance with performance and safety standards. The following is an in-depth functional test procedure for PV inverters:

• TEST SETUP

The test setup should include the following equipment:

o PV inverter

o Solar Array Simulator

o Grid Simulator / AC Load

o Oscilloscope (Optional)

o DMM (Optional)

o Communication to the Solar Inverter (Optional)

o Temperature sensor (optional)

• INDUSTRY STANDARD FUNCTIONAL TESTS

oInput Voltage Range

oOutput Current Range

oPower Efficiency

oFrequency Regulation

oVoltage Regulation

oCurrent Regulation

oLVRT /HVRT

oMPPT

oAnti-Islanding

oOver Current Protection

oOver Voltage Protection

oUnder Voltage Protection

oOver Frequency Protection

oUnder Frequency Protection

oShort Circuit Protection

oTemperature Test

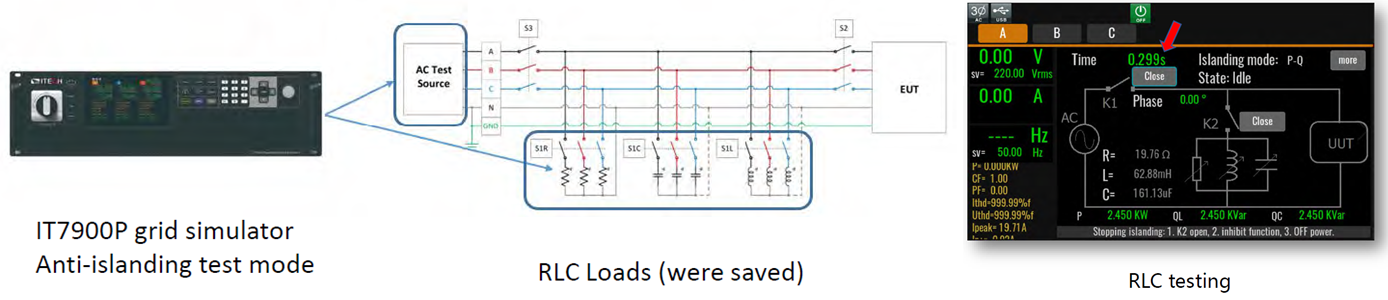

RLC simulation

Islanding RLC simulation mode

IT7900P grid simulator = traditional power grid simulator + RLC Load - Cost saving

The regulations require test equipment:

a)

meet the requirements of the islanding test circuit topology diagram, support single-phase/three-phase

b)

reactive power, active power and R L C are settable

c)

the RLC Load parameters of each phase can be set individually, and the simulation matches the balance/unbalance

d)

provide Anti-islanding protection time test function (as shown on the right)

LVRT&HVRT

The grid voltage may drop or rise briefly due to faults or changes of load. At this time, the distributed power generation equipment connected to the grid, such as wind turbine inverters and PV inverters etc. - LVRT: After the grid voltage drops, it can continue to operate without being disconnected from the grid within the specified voltage drop time, and at the same time, it can provide reactive current to support the grid. - HVRT: When the grid voltage suddenly rises, within a certain voltage surge range and time interval, it can ensure continuous operation without being disconnected from the grid.

Wind Energy Converter System (WECS)Test

Test items

oVoltage deviation, frequency deviation adaptability test

oThree-phase voltage unbalance adaptability

oHarmonic voltage adaptability

oHigh voltage/low voltage ride through test

oPower Quality Analysis

Advantages

oVoltage up to 700V through Reverse function

o50th harmonic simulation function

oLIST/SWEEP/Surge&Sag

oSingle/Three Phase, simulate three Phase unbalance

oBuilt-in islanding test mode

oBuilt-in USB/CAN/LAN and abundant Digital IO

Quick Delivery

don't wait too long

Technical Support

Specialists online

Fast Shipping

We ship internationally!

Quick Response

personalized attention